Week2 Summary_Bharadwaj et al. (2007)_ Vicky Xu

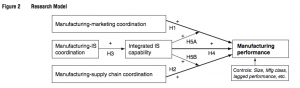

Since the prior literature on coordination and manufacturing performance has been limited to focusing on a firm’s information systems capability and its integration with supply chain capabilities, the increased role of IT in manufacturing performance and dynamically changing business need require manufacturing and information systems (IS) functions to evaluate IT’s support of business goals and develop new capabilities to support a new dimension of inerfunctional coordination. Bharadwaj et al. (2007) develop an integrative model of manufacturing performance that includes an integrated information systems construct and manufacturing-IS (Mfr-IS) coordination in conjunction with manufacturing-marketing (Mfr-Mkt) and manufacturing-supply chain (Mfr-SC) coordination, providing a more complete picture of the true drivers of manufacturing performance which simultaneously considers the effects of a firm’s integrated IS capability in conjunction with interfunctional and interorganzational coordination mechanisms.

Bharadwaj et al. (2007) also develop a conceptual framework as the following:

Bharadwaj et al. (2007) tests the model by using data collected from a national survey of manufacturers (about 169 firms) and archival manufacturing performance data from COMPUSTAT (about 126 firms). And they use the general system-form of the model to test the hypotheses. In the first step, the responding firms were separated into two groups: firms with scores greater than the mean of the sum of the three coordination variables (coded as one) and firms with scores lesser than the mean of the sum of the three coordination variables (coded as zero). After using a three-stage least-squares analysis, a hierarchical regression analysis and moderated regression analysis, all the hypothesized relationships were statistically significant.

The significant contributions of this study include: (1). Exploring the role of Mfr-Is coordination and integrated IS capability in conjunction with the traditional coordination drivers in explaining manufacturing performance. (2). Presenting an examination of the role of manufacturing-IS coordination in contemporary manufacturing firms.

Leave a Reply

You must be logged in to post a comment.